2026 Top Insights into Fertilizer Factory Innovations and Trends

In the dynamic world of the fertilizer factory industry, innovation plays a crucial role. Experts like Dr. Emily Carter have emphasized its importance, stating, "Sustainable practices in fertilizer production are the future." As the demand for innovative solutions grows, manufacturers are increasingly exploring new technologies and processes.

Fertilizer factories are adapting to emerging trends. For instance, precision agriculture is changing how fertilizers are applied. This shifts traditional methods, prompting many factories to rethink their strategies. However, it is not without challenges. Some factories struggle to keep pace with technological advancements. Maintaining sustainability while ensuring efficiency is a delicate balance.

Innovation in the fertilizer factory sector can lead to impressive outcomes. Yet, it requires careful planning and investment. The journey is fraught with obstacles, and many companies still face hurdles. While the path forward is promising, reflection on current practices is essential. Only then can the industry thrive responsibly and sustainably.

Innovative Technologies Driving Fertilizer Manufacturing Efficiency

Innovative technologies are reshaping fertilizer manufacturing. Automation is a game changer. Factories are installing advanced robotics. These machines increase precision in the production process. They handle materials more efficiently, reducing waste. Additionally, real-time data monitoring improves decision-making.

Sustainability is a key focus. New processes reduce energy consumption. For example, some plants utilize renewable energy sources. This shift helps lower carbon footprints. However, challenges remain. Not all facilities can adopt these technologies easily. High initial costs and training needs can be barriers.

Integrating smart technologies is essential. IoT devices track equipment performance. Data analytics offers insights into usage patterns. Yet, the industry must adapt to these changes gradually. Resistance may occur as workers adjust to new systems. Balancing innovation and human factors is crucial for success.

2026 Top Insights into Fertilizer Factory Innovations and Trends

| Innovation Type | Description | Impact on Efficiency | Implementation Year | Adoption Rate (%) |

|---|---|---|---|---|

| Precision Fertilization | Use of sensors and data analytics to optimize fertilizer application | Increase in nutrient use efficiency by 25% | 2024 | 60% |

| Bio-Based Fertilizers | Utilizing organic materials as substitutes for chemical fertilizers | Reduction of carbon footprint by 30% | 2025 | 45% |

| Smart Manufacturing | Automated processes utilizing IoT and AI for monitoring | Productivity increase by 40% | 2026 | 50% |

| Nano-Fertilizers | Revolutionary fertilizers at the nanoscale that enhance absorption | Increase in crop yields by 15% | 2023 | 25% |

| Circular Economy Practices | Recycling waste products into fertilizer | Waste reduction by 35% | 2025 | 40% |

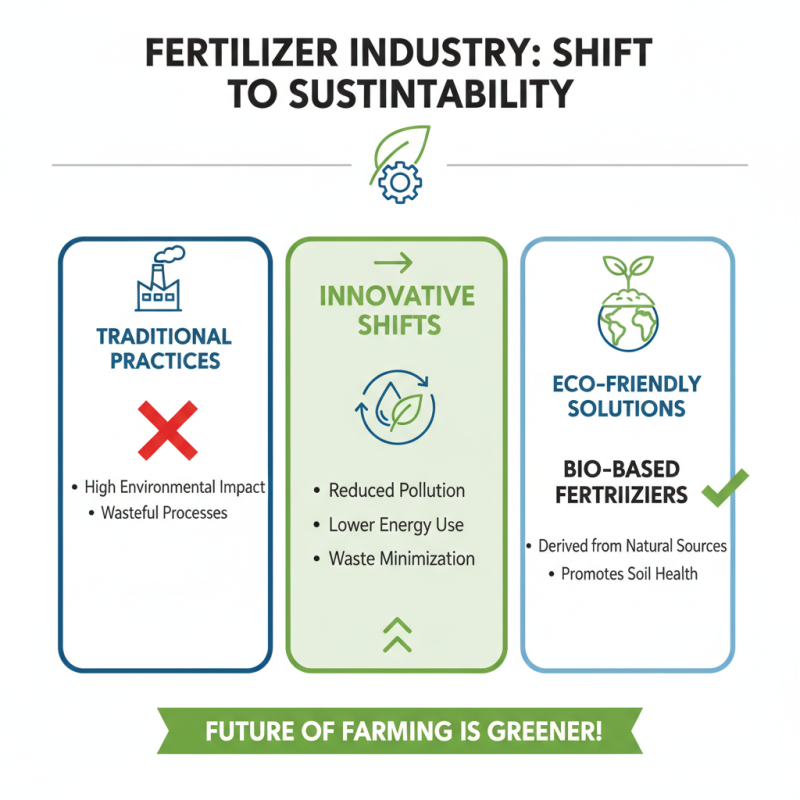

Sustainable Practices in Fertilizer Production: Trends and Innovations

The fertilizer industry is undergoing significant changes, focusing on sustainability. Innovative practices are emerging to reduce environmental impact. Companies are exploring eco-friendly processes that minimize waste and energy use. For instance, some are turning to bio-based fertilizers. These options are derived from natural sources, promoting soil health.

In addition, recycling is becoming a key trend. Reusing organic materials can cut costs and lessen pollution. However, this approach is not without challenges. The quality of recycled products can vary, and more research is needed. Not all manufacturers are equipped to adapt quickly, leading to inconsistent offerings.

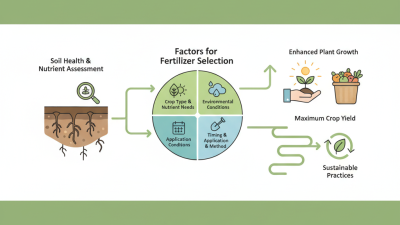

Moreover, adopting technology for precision agriculture is gaining traction. Smart sensors and data analytics help optimize fertilizer use. This can enhance crop yields while reducing excess application. Yet, the investment required can be a barrier for some. It raises questions about accessibility and equity in the industry. The balance between innovation and practical implementation remains a topic of reflection.

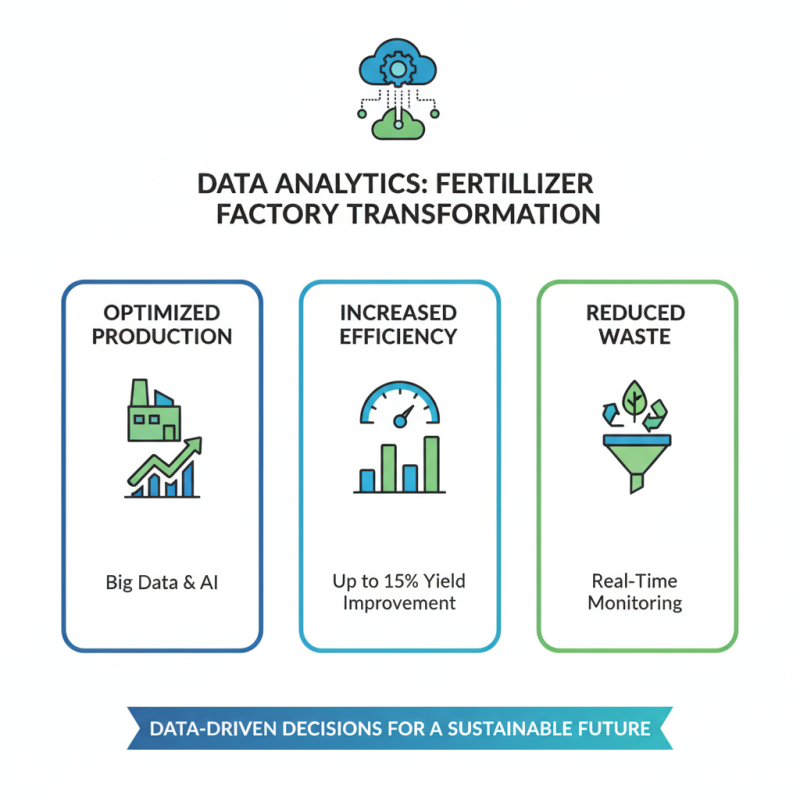

The Role of Data Analytics in Modern Fertilizer Factories

Data analytics is transforming fertilizer factories. By leveraging big data, factories can optimize production processes. This innovation leads to higher efficiency and reduced waste. Reports indicate that data-driven decisions can improve yield by up to 15%. This approach allows for real-time monitoring of materials and workflows.

Understanding soil health is crucial. By analyzing data from soil samples, farmers can receive tailored recommendations. Precision agriculture relies heavily on analytics to determine the right fertilizer type and application timing. A recent study revealed that 70% of farmers reported improved crop health through data integration.

**Tip:** Invest in training staff on data tools. A knowledgeable team can unlock insights that drive growth.

However, challenges remain. Many factories may struggle with data integration. Legacy systems can hinder the flow of information. It’s vital for businesses to reflect on their current practices and adapt. Embracing these innovations is essential for staying competitive in a rapidly evolving market.

**Tip:** Start small with analytics projects. Gradually scaling up can mitigate risks associated with technological adoption.

Emerging Fertilizer Products to Meet Global Agricultural Demands

Emerging fertilizer products are revolutionizing agriculture. As global food demand rises, innovation is crucial. New fertilizers focus on efficiency and sustainability. They provide nutrients more effectively, leading to better crop yields.

Farmers face many challenges today. Changes in climate and soil health impact agriculture. Innovative fertilizers can help address these issues. Some products enhance nutrient absorption, reducing waste. Others include bio-based components for sustainable farming. This shift towards eco-friendly options is essential.

Tips: Test new products on a small scale first. Monitor crop responses closely. Adapting to innovations can be trial and error. Stay informed about emerging trends. Join local farmer groups to share insights. Understanding soil health will also guide your choices.

Future Challenges and Opportunities in Fertilizer Factory Operations

The fertilizer industry faces significant challenges ahead. As global demand for food increases, factories must innovate. By 2026, production needs to rise by over 30% to meet these demands. Current technologies may not suffice. Efficiency, sustainability, and cost-effectiveness are vital.

Investing in automation is one potential path. Data from industry reports show that automated systems can boost productivity by up to 25%. However, the initial investment can be daunting for smaller operations. Some factories may struggle to keep pace. Understanding local market needs is essential.

Tips: Focus on upgrading existing systems instead of complete overhauls. Incremental changes can yield substantial improvements. Collaborating with local farmers may provide insights into better production methods. Emphasizing sustainability will not only benefit the planet but also open doors to new markets. Adapting to these trends is crucial for long-term survival.

2026 Fertilizer Factory Innovations: Trends and Insights

This chart illustrates the importance level of various innovative trends anticipated in fertilizer factory operations by 2026. As the industry shifts towards more sustainable and advanced practices, understanding these trends can help companies navigate future challenges and leverage opportunities.

Related Posts

-

Top 5 Fertilizer Shops Near Me for All Your Gardening Needs

-

How to Choose the Best Fertilizer Distributor for Your Gardening Needs

-

How to Choose the Right Agricultural Fertilizer for Maximum Crop Yield

-

Top Benefits of Using Ag Fertilizer for Optimal Crop Growth?

-

10 Essential Tips for Finding the Best Wholesale Fertilizer Suppliers?

-

Find the Best Local Fertilizer Shops Near Me for 2025 Gardening Success