Top 10 Aluminum Composite Panel Manufacturers You Should Know?

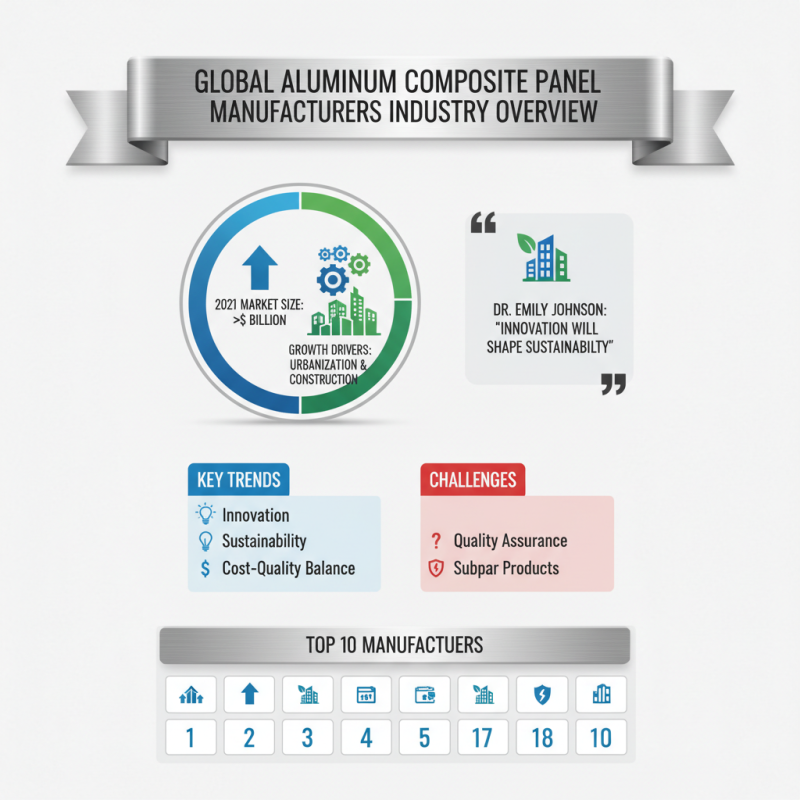

The aluminum composite panel manufacturers industry plays a vital role in modern architecture. In 2021, the global market size was valued at over $5 billion, with expected growth driven by urbanization and construction activities. According to industry expert Dr. Emily Johnson, “Innovation in aluminum composites will shape the sustainability of future buildings.” This emphasizes the importance of staying informed about leading manufacturers.

As competition increases, awareness of top players in the aluminum composite panel market becomes crucial. With sustainability at the core of consumer preferences, manufacturers are pushed to adopt eco-friendly practices. The challenge lies in balancing cost and quality, as not all manufacturers keep pace with evolving standards. By identifying the top 10 manufacturers, stakeholders can make informed decisions.

Quality assurance remains a significant concern. Many manufacturers struggle to maintain consistent product standards. The presence of subpar products in the market raises questions about reliability and safety. Thus, understanding the top aluminum composite panel manufacturers is essential for those invested in this evolving industry.

An Overview of Aluminum Composite Panels and Their Applications

Aluminum composite panels (ACP) have transformed the construction industry. These panels consist of two thin layers of aluminum enclosing a non-aluminum core. This composition leads to lightweight yet durable materials. According to a recent market report, the global ACP market is expected to reach approximately $6 billion by 2027, showcasing strong growth in various sectors.

ACP applications are diverse. They are extensively used in building facades, interior walls, and signage. The panels are not just sleek but also energy-efficient. They help in reducing energy consumption in buildings significantly. However, challenges remain. Issues related to fire safety have been raised, underscoring the need for compliance with rigorous regulations. A report indicates that around 20% of ACP installations have faced scrutiny for safety standards, pushing for improvements in manufacturing practices.

In interior design, ACP offers aesthetic versatility. Designers often desire unique shapes and finishes to enhance visual impact. The market shows a trend towards eco-friendly materials, even in ACP production. Yet, many manufacturers still rely on traditional methods that are less sustainable. This creates a gap between consumer expectations and industry practices. Addressing these inconsistencies is crucial for future growth in the ACP sector.

Top 10 Aluminum Composite Panels Manufacturers - Market Share Overview

Key Factors to Consider When Choosing Aluminum Composite Panel Manufacturers

Choosing the right aluminum composite panel manufacturer involves several key factors. Quality is foremost. Panels must meet standards for durability and resistance. Poor quality can lead to issues later on. This is costly and time-consuming to rectify.

Another aspect to consider is the range of products offered. Manufacturers should provide a variety of colors and finishes. This flexibility helps you find the right look for your project. Not all manufacturers have extensive selections, limiting your choices.

Additionally, evaluate their customer support. A responsive manufacturer can make a big difference. You might encounter challenges during installation. Quick assistance is crucial. It's worth reaching out to test their responsiveness before making a decision.

Tips: Check for warranties. A solid warranty indicates confidence in the product. Do sample testing. This will help ensure the panels meet your specific needs. Finally, assess their reputation in the industry. Look for reviews or recommendations. A trusted manufacturer is invaluable.

Top 10 Leading Manufacturers in the Global Aluminum Composite Panel Market

The global aluminum composite panel market is thriving. Many manufacturers play an essential role. These companies offer unique products and solutions catering to diverse needs. Their innovations drive architectural design forward. The panels provide aesthetic appeal along with functional advantages.

In this competitive landscape, companies prioritize quality and sustainability. Some struggle to balance cost and performance. This challenge is critical, as clients look for durability and elegance. Advanced technology is often required to stay ahead. Manufacturers explore eco-friendly materials and production methods.

While there are leaders in the industry, not all succeed. The market is dynamic, and adaptation is key. Companies must learn from both successes and failures. Innovation does not come easy; it demands constant improvement and reflection. In the end, the pursuit of excellence in aluminum composite panels continues to shape the industry.

Market Trends: Growth Rate and Innovations in Aluminum Composite Panels

The aluminum composite panel (ACP) market is rapidly evolving. According to a recent report by Research and Markets, the global ACP market is expected to grow at a CAGR of 6.2% from 2023 to 2028. This growth is fueled by rising urbanization and the increasing demand for lightweight materials in construction. Cities are expanding, and innovative designs are in high demand.

Innovations in ACP technology have emerged, focusing on sustainability and energy efficiency. Manufacturers are now exploring eco-friendly materials and production methods. For instance, some are integrating solar-reflective coatings, which enhance energy efficiency in buildings. However, the challenge remains in balancing cost and quality. Many companies face the dilemma of producing high-performance panels without significantly increasing their prices.

The increasing popularity of aesthetic designs is another noteworthy trend. ACPs are not just functional; they also enhance visual appeal. Leveraging advanced printing technology allows for customized designs. Yet, with more choices comes the risk of inconsistency in quality. Ensuring robust quality control measures is vital as the market continues to innovate. As growth persists, reflection on these challenges is necessary for sustainable advancement in the ACP industry.

Sustainability Practices Among Top Aluminum Composite Panel Producers

Sustainability is becoming crucial for aluminum composite panel producers. Companies increasingly focus on eco-friendly practices. A recent report shows that about 75% of manufacturers prioritize sustainable sourcing of raw materials. This shift reflects growing consumer demand for environmentally responsible products.

Many top producers implement recycling programs for their materials. These initiatives help reduce waste and conserve resources. It’s estimated that recycling aluminum can save up to 95% of energy compared to producing new aluminum from ore. This statistic highlights the importance of sustainable practices in the industry.

Tips:

Consider materials that meet sustainability standards. Look for certifications that demonstrate environmental commitment. Monitor how brands report their waste management strategies. Many companies still grapple with meeting high sustainability benchmarks; transparency is essential. Challenge yourself to choose suppliers who prioritize eco-friendly production.

Top 10 Aluminum Composite Panel Manufacturers You Should Know? - Sustainability Practices Among Top Aluminum Composite Panel Producers

| Rank | Manufacturer | Annual Production (tons) | Sustainable Practices | Recycling Program | Certifications |

|---|---|---|---|---|---|

| 1 | Manufacturer A | 5000 | Green energy sourcing | Active | ISO 14001 |

| 2 | Manufacturer B | 4500 | Low-emission production | Planned | LEED Certified |

| 3 | Manufacturer C | 6000 | Use of recycled materials | Active | ISO 9001 |

| 4 | Manufacturer D | 7000 | Carbon footprint reduction | Active | Green Guard Certified |

| 5 | Manufacturer E | 5000 | Waste reduction initiatives | Planned | ISO 14001 |

| 6 | Manufacturer F | 8000 | Energy-efficient production | Active | ISO 50001 |

| 7 | Manufacturer G | 6500 | Community engagement programs | Active | Cradle to Cradle Certified |

| 8 | Manufacturer H | 9000 | Resource efficiency measures | Planned | ISO 14064 |

| 9 | Manufacturer I | 4800 | Sustainable sourcing of materials | Active | BIFMA Certified |

| 10 | Manufacturer J | 5200 | Pollution control technologies | Planned | ISO 14001 |